Specification

- ઉપયોગ/એપ્લિકેશન્સ

- Industrial

- આવર્તન

- હર્ટ્ઝની (હર્ટ્ઝ)

- લક્ષણ

- High Performance

- ટેકનોલોજી

- Ion Exchange Resin Method

- જળ સ્ત્રોત

- પાવર સ્રોત

- Electric

- વોલ્ટેજ

- વોલ્ટ (વી)

- આપોઆપ ગ્રેડ

- શુદ્ધતા સ્તર

- 95%

- સામગ્રી

- FRP/MS

- ક્ષમતા

- Ltr/hr

- ઇન્સ્ટોલેશન પ્રકાર

Trade Information

- Minimum Order Quantity

- 1 Unit

- પુરવઠા ક્ષમતા

- દર મહિને

- ડિલિવરી સમય

- દિવસો

- મુખ્ય સ્થાનિક બજાર

About

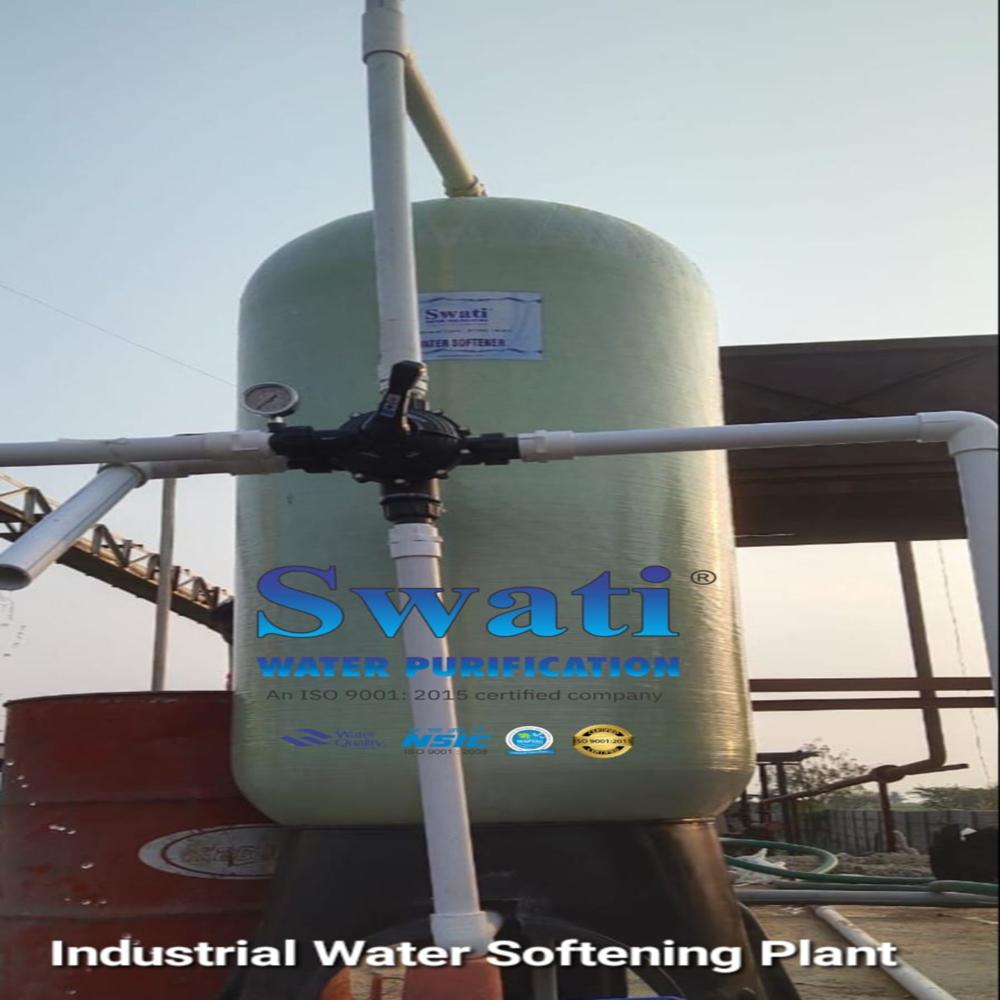

A Water Softeners are Facility Designed to Treat Hard Water By Removing Minerals Such As Calcium (Ca2+) and Magnesium (Mg2+), Which Cause Water Hardness. These Minerals Can Lead to Scaling and damage In Equipment, Pipes, Boilers and Cooling Systems. Water Softening is Critical in many Industrial Processes to Prevent Scaling, Reduce Energy Consumption and Prolong the Life of Machinery and Infrastructure.

Water Softeners Manufacturer

An Industrial Water Softener Can Be Called by Several Names, Including Commercial Water Softener, Hard Water Softener, Industrial Water Softener System, Ion Exchange Softener, Boiler Water Softener, Cooling Tower Water Softener, Demineralizer, Water Softening Plant, Softener, Water Softener Plant, Hard Water Softener Plant, Softener For Hard Water, Ion Exchange Water Softening System, Industrial Water Treatment System, Water Softener System, Ion Exchange Water Softening System.

We Are Manufacturers & Suppliers In Ahmedabad, Gandhinagar, Gujarat, India, Sanand GIDC, Mehsana, Vitthalapur, Mandal Bechraji Special Investment Region(MBSIR), Halol GIDC, Bavla Kerala GIDC, Dahej SIR & PCPIR(Petroleum, Chemicals and Petrochemicals Investment Region), Dholera SIR, GIDC Industrial Area(Gujarat Industrial Development Corporation), MIDC Industrial Area(Maharashtra Industrial Development Corporation), MPIDC Industrial Area(Madhya Pradesh Industrial Development Corporation), RIICO Industrial Area(Rajasthan State Industrial Development & Investment Corporation), PSIDC(Punjab State Industrial Development Corporation), SEZs Area(Special Economic Zones), SEEZ Area(Solar Energy Enterprises Zone) In Rajasthan, Peenya Industrial Area In Bengaluru(Bengalore, Karnataka). It Removes Hard Water Minerals from Water and Replaces Them with Softer Minerals. It Consisits Of a Mineral Tank, Brine Tank and Other Components.

Capacities: 500-50000 Liters per Hour (LPH)

Some Industrial Water Softening Plants Have a Capacity of 5,000 liters Per Hour (LPH)

Other Industrial Water Softening Plants have a Capacity Of a 1200 Liters of Resin.

Some Industrial Water Softening Plants Have a Capacity of 250 Cubic Meters per Hour.

Materials We Used: FRP, LLDP, MS, MSEP, MS Rubber Lining and Stainless Steel

Components: Pre-filters, Water Softener Vessel with Resin, Brine Tank and Multiport Valves/Diaphram Valves.

Water Softener Stages:

Pre-Treatment System Like Sediment Filters, Activated Carbon Filters

Ion-Exchange Process Like Softening Resin, Cation Exchange, Regeneration

Regeneration System

Control and Monitoring System Like Control Panel, Flow Meters, Pressure Gauges, Automatic Regeneration

Brine Storage and Disposal

Pre-Treatment System (Optional) : Filtration, pH Adjustment

Process Of Water Softeners:

1. Ion Exchange:

The Primary Process Used in Industrial Water Softening Plants is ION Exchange, Where Hardness-Causing ions (Ca2+ and Mg2+) are exchanged with Sodium (Na+) Or Potassium (K+) ions.

This Process Occurs When the Hard Water Flows through a Resin Bed, and The Hardness Ions Stick to the resin, While Sodium Ions are Released into the Water.

2. Regeneration :

When The Ion-Exchange Resin Becomes Saturated With Hardness Ions, The System Enters a Regeneration Cycle.

During Regeneration, The Resin Is Flushed With a High-Concentration Brine Solution. The Sodium Ions in the Brine Displace the Calcium and Magnesium Ions On the Resin Beads, Restoring the Resins Ability To Soften Water.

The Brine (Now Containing Calcium, Magnesium and Sodium) is Then Flushed Away and the Softening Plant Is Ready for the Next Cycle.

3. Rinse Cycle:

After Regeneration, the System Typically Undergoes a Rinse Cycle, Where Excess Brine and Contaminants are Washed out Of the Resin Bed, Ensuring That the Softener Operates Efficiently.

Applications Of Water Softener In Different Industries:

Industrial Water Softening Plants Are Used in Many Industries, Including Industrial Boilers Washing Processes, Boiler Feed Water, Cooling Water, Steel Mills, Laboratories, Mining, Chemical Processing, Cleaning Processes, Electronics manufacturing, Power Plants, Refineries And Chemical Manufacturing And Also..

Food and Beverage: Prevent Scale Buildup in Boilers and Steamers.

Hospitality: Provides Soft Water For Bathing, Laundry and Dishwashing

Textile: Prevents Fabric Discoloration and Improves Laundry Efficiency.

Laundry: Maintains Fabric Quality and Reduces Detergent Consumption.

Healthcare: Prevents Scale Buildup In Sterilization Equipment And Ensure Medical Devices, Instruments are Cleaned and Sanitized

Pharmaceutical: Meets Strict Purity Standards For Ingredient Preparation, Equipments Cleaning and Steam Generation.

Manufacturing: Prevents Mineral Buildup In Pipes and Water Heaters Also Saves Money On Repairs From Unnecessary Wear and tear On Industrial Equipment.

Water Treatment Plants: Softening Water in municipal and industrial water treatment systems to improve overall water quality and prevent damage to distribution infrastructure.

Price: Â

- 50

- 100

- 200

- 250

- 500

- 1000+

વધુ Products in Water Softeners Category

220-340 વી ડોમેસ્ટિક વોટર સોફ્ટનિંગ સિસ્ટમ

ઉપયોગ/એપ્લિકેશન્સ : Domestic/ Commercial

આપોઆપ ગ્રેડ : Manual

સામગ્રી : FRP

ઇન્સ્ટોલેશન પ્રકાર : Other

ક્ષમતા : લિ

કિંમતની એકમ : એકમ/એકમો

5000 એલપીએચ વોટર સોફ્ટનર સિસ્ટમ

ઉપયોગ/એપ્લિકેશન્સ : Domestic/Commercial

આપોઆપ ગ્રેડ : Semi Automatic

સામગ્રી : FRP

ઇન્સ્ટોલેશન પ્રકાર : Other

ક્ષમતા : લિ

કિંમતની એકમ : એકમ/એકમો

પૂછપરછ મોકલો

પૂછપરછ મોકલો મને મફતમાં કૉલ કરો

મને મફતમાં કૉલ કરો